Combined Belt Filter Press & Belt Thickener

Enviroflex GmbH – Advanced Solutions for Sludge Thickening & Dewatering

Enviroflex GmbH, based in Austria, is a leading provider of innovative solid-liquid separation technologies. With years of expertise in the field, we specialize in complete, tailor-made solutions for municipal and industrial sludge treatment—from primary thickening to final dewatering.

Our current catalogue focuses exclusively on our high-performance belt presses and belt thickeners, engineered to deliver reliable, efficient, and cost-effective results for a wide range of sludge types.

Product Highlights

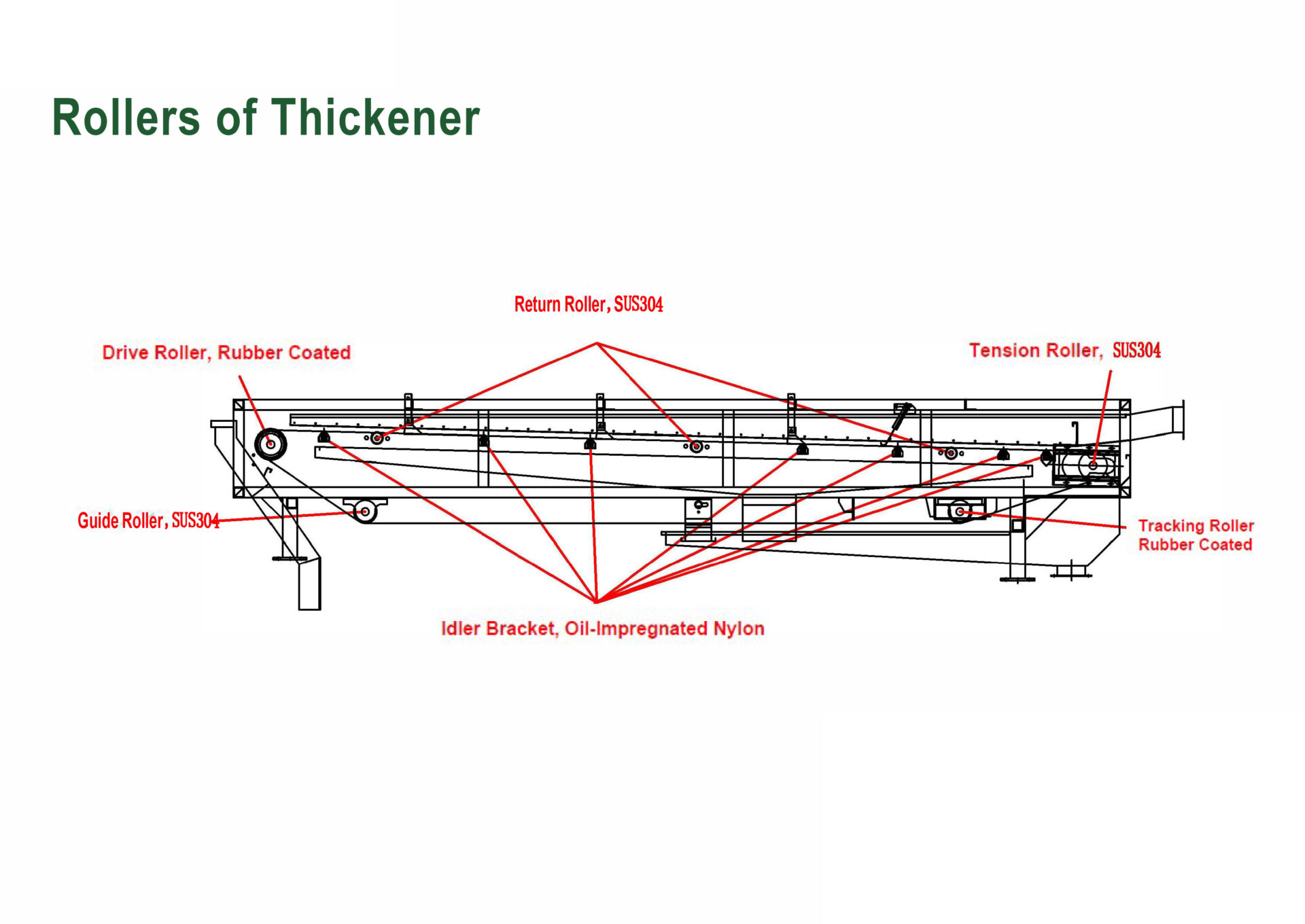

- Gravity Belt Thickeners: Ideal for thickening dilute sludge (e.g., primary or secondary sludge) to a manageable consistency, minimizing volume before further treatment or disposal.

- Belt Filter Presses: Designed for continuous dewatering of thickened or illiquid sludge, producing a dry cake with high solids content.

- Integrated Systems: Combined units with both belt thickener and stages in one frame—perfect for thin sludges like waste activated sludge (WAS), offering a compact and fully automated process.

Key Advantages of Enviroflex Belt Technology

- ✅ High Capture Rate – Advanced belt and roller design ensures minimal solids loss in filtrate (typically <1%), protecting downstream systems and optimizing efficiency.

- ✅ High Dry Solids Content (DS%) – Precision-engineered pressure and shear zones, including high-pressure „tension“ rollers, achieve excellent cake dryness, even with difficult sludges.

- ✅ Low Wash Water Consumption – Efficient belt cleaning systems reduce water use and operational costs.

- ✅ Wide Belt Selection – High-quality belts available in various weave patterns, air permeability, and chemical resistance grades, customized for specific sludge characteristics.

- ✅ Robust, Low-Maintenance Design – Built for long service life with corrosion-resistant materials and minimized mechanical complexity.

- ✅ Flexible Operation – Adjustable belt speed, pressure zones, and polymer dosing for optimized performance under varying sludge loads.

- ✅ Fully Automated Control Systems – Integrated with user-friendly HMIs and optional SCADA interfaces for remote monitoring and process optimization.

- ✅ Compact Footprint – Space-saving designs available for containerized and

- retrofit applications.

Complete System Integration

In addition to manufacturing the belt thickening and dewatering units, we supply and integrate the full process chain:

- Sludge feed tanks and pumps

- Polymer preparation and dosing units (powder or emulsion)

- Polymer mixing and maturation tanks

- Sludge conveyors (screw, belt, shaftless)

- Filtrate handling systems

- Electrical control panels and automation (with CE compliance and ISO-certified production)

🔧 Although this catalogue focuses on • Integrated Systems: Combined units with both belt thickener and belt press stages in one frame, we also offer other belt presses and belt thickener alone as well as other sludge dewatering systems such as multi-disk screw presses for compact and low-speed operations. Contact us for custom configurations.

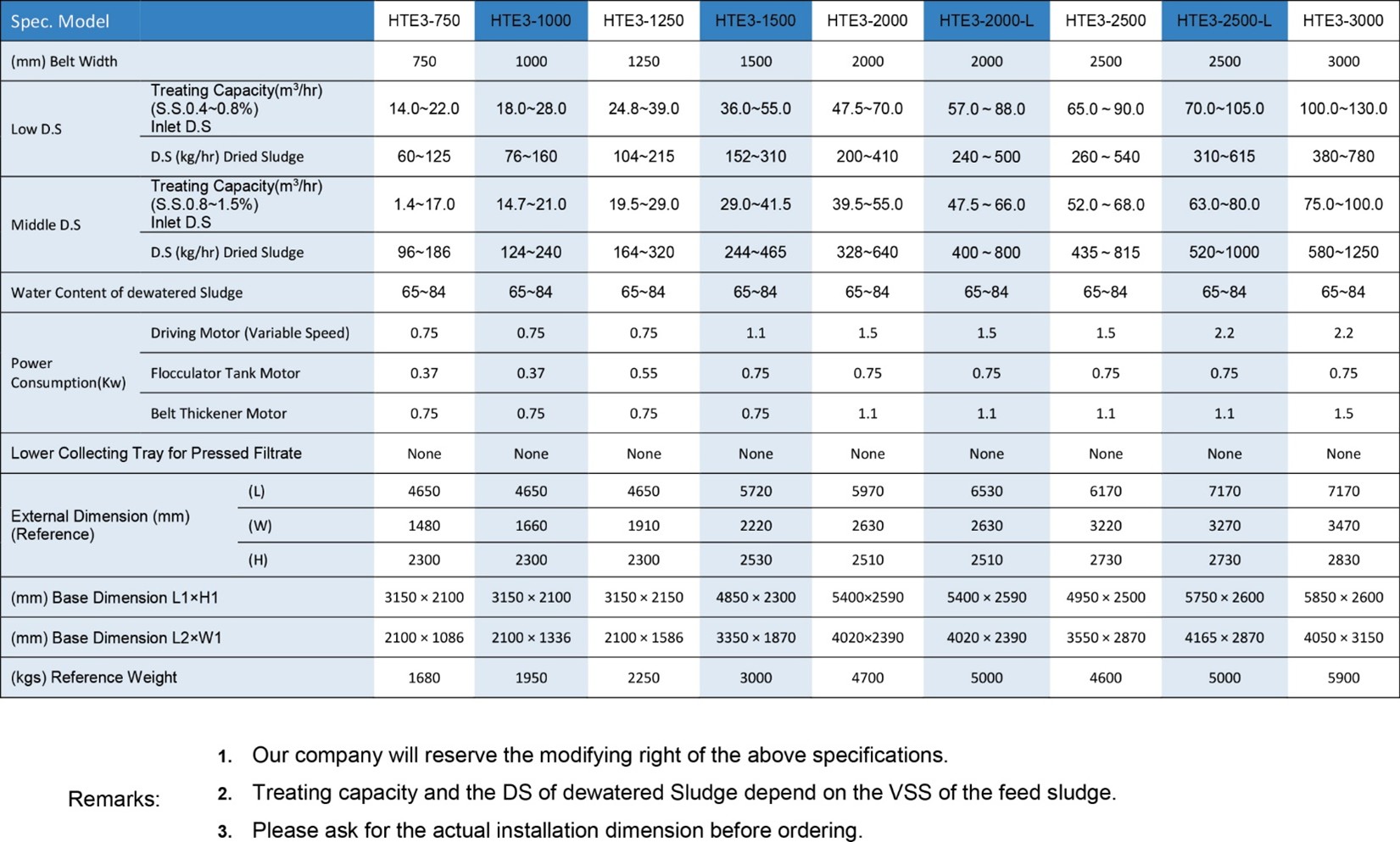

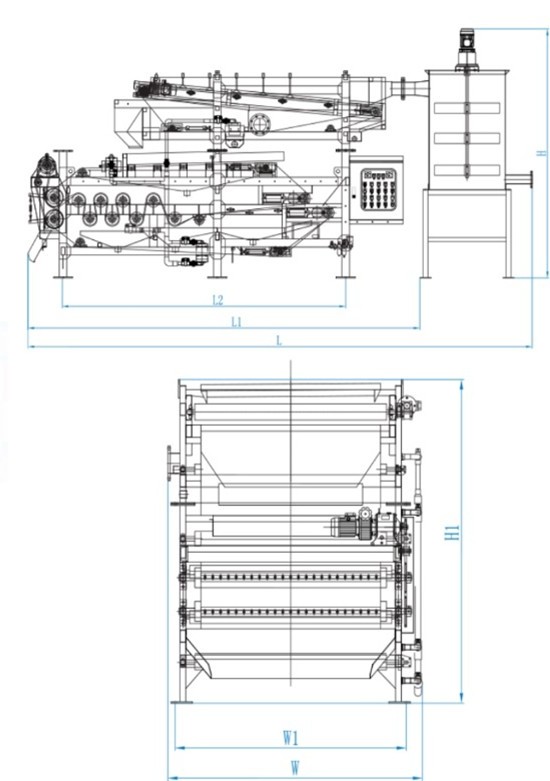

Technical Data & External Dimensions of Belt Filter Press

Sludge Dewatering Application

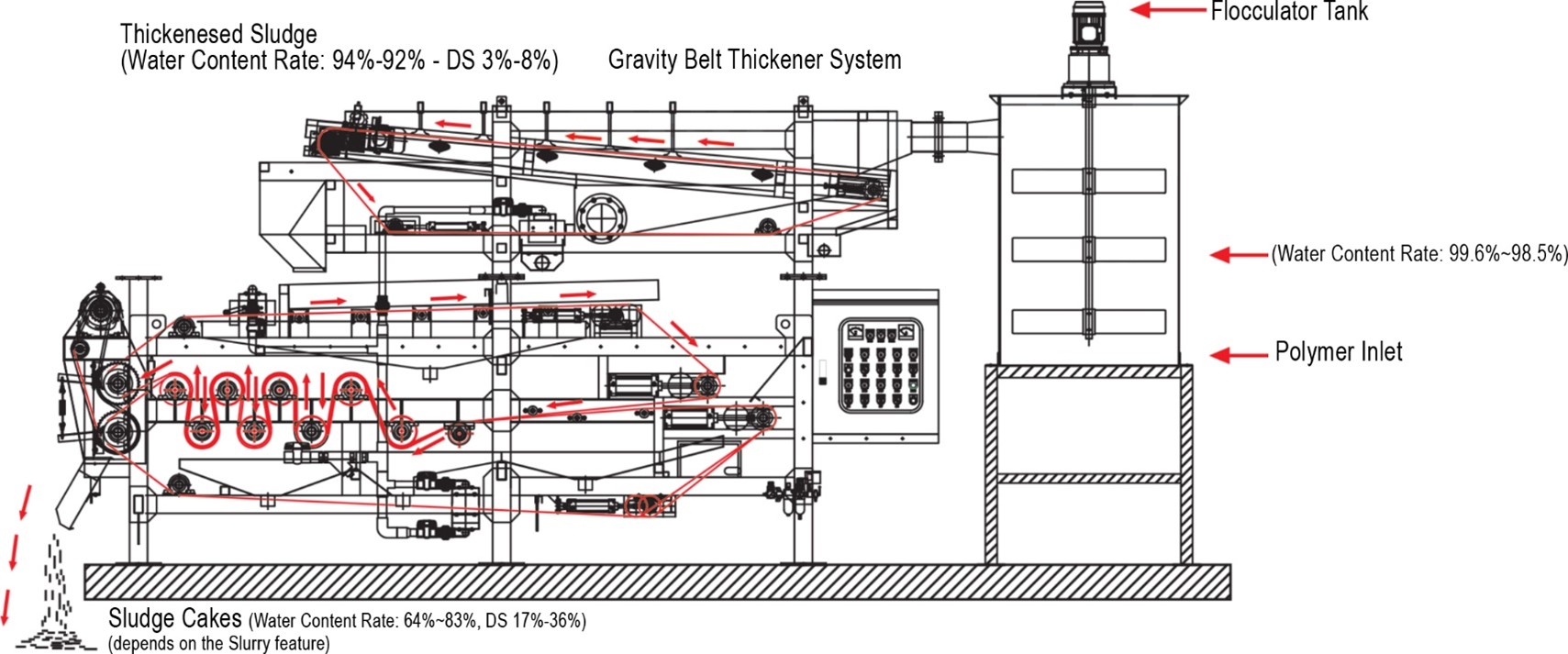

Gravity Belt Thickening/Dewatering Belt Filter Press (Triple-Belt Filter Press)

Features of Belt Filter Press

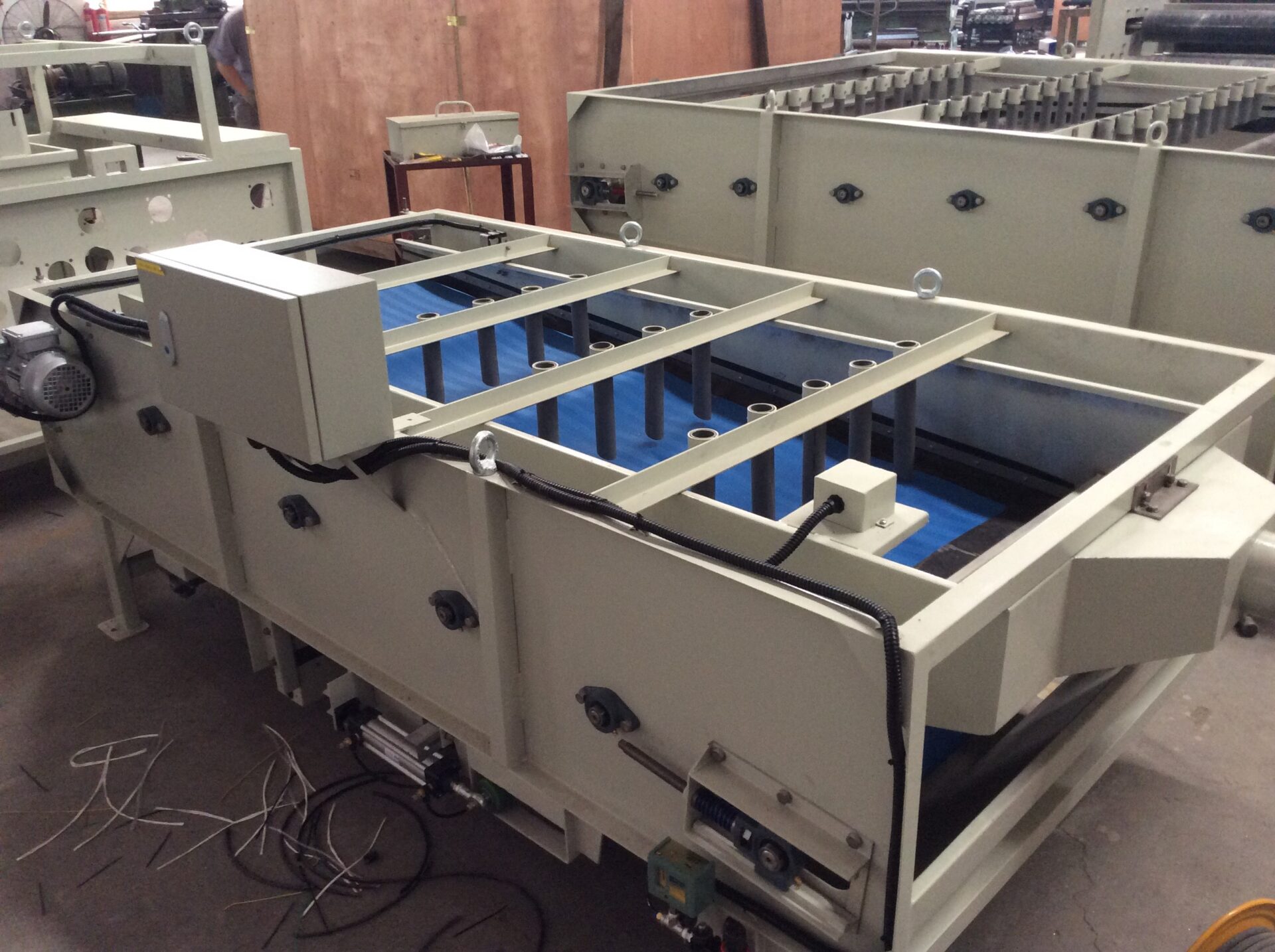

Combined Belt Thickener & Belt Filter Press Unit Model: HTE3-2000L For Municipal and Industrial Sludge Dewatering

1. Machine Overview

The HTE3-2000L is a fully integrated unit that combines a gravity belt thickener and belt filter press to provide efficient sludge dewatering for a wide range of sludge types. Its compact design, energy efficiency, and automation features make it ideal for both municipal and industrial applications.

Working Principle

- Polymer-Sludge Mixing

Raw sludge is mixed with a flocculant in a pre-dosing and mixing tank equipped forming flocs that facilitate water release.

- Gravity Thickening

The flocculated sludge is distributed onto a gravity belt , where free water drains through the moving porous belt via gravity, concentrating the solids.

- Belt Press Dewatering

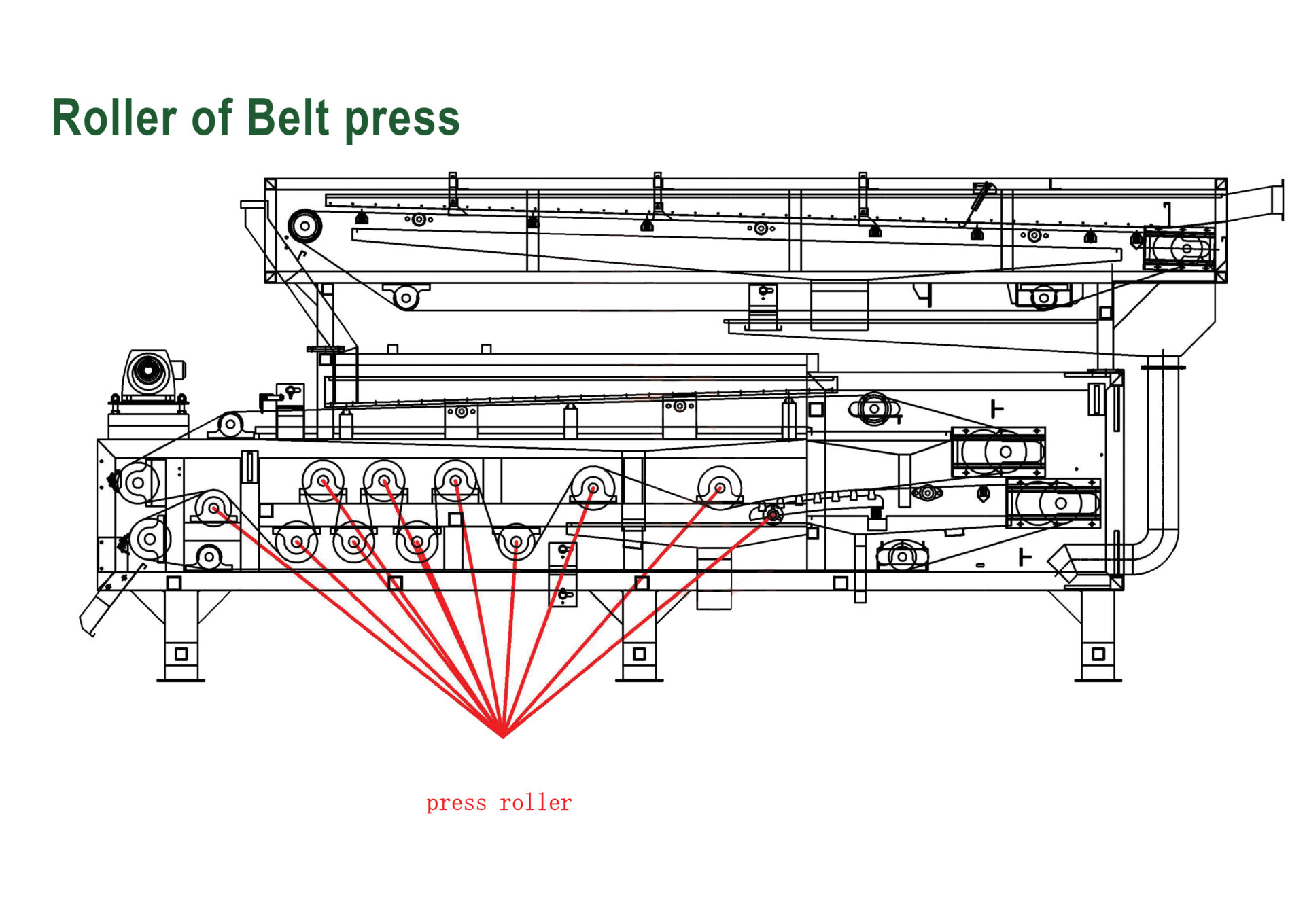

The thickened sludge is conveyed to the press section and compressed between two belts across 11 rollers, producing a dewatered sludge cake with high dry solids (DS) content.

- Automatic Belt Cleaning

A high-efficiency water spray system continuously cleans the belts via flush nozzles within a closed pipeline. No mechanical brushes are used.

2. Features & Benefits

- Fully Integrated System – One compact unit for thickening and dewatering.\

- CE, Manufactured with compliance with CE safety regulation

- Low Polymer Consumption – Polymer added only once; no secondary dosing.

- Low Wash Water Consumption – Single high-efficiency pump (14 m3/h).

- High Capture Efficiency – 290% solids retention.

- High Cake Solids – 16-20% DS depending on sludge type and characteristics like VSS of sludge as well as polymer flocculant efficiency

- Low Filtrate Solids – 10-30 mg/L from the thickening section.

- Durable Belts – Woven polyester monofilament belts with long lifespan.

- Pneumatic Belt Control -Automatic alignment and tensioning using pneumatic components.

- Easy Maintenance – Roller access and belt replacement designed for quick service.

- Robust Frame – Coated carbon steel or stainless steel (SS304/316) as per order of customer

- Quality Drive Components

Press Section Drive: Nord (Germany)

Thickener & Agitator Drive: SITI (Italy)

Parameter

Belt Width

Thickener Belt Length

Dewatering Belt Length {Upper)

Dewatering Belt Length {Lower)

Belt Speed {Thickener)

Belt Speed {Press)

Number of Press Rollers

Expected Cake Dryness

Solids Capture Rate

Filtrate Solids {Thickener)

Mixing Tank Motor

Thickener Belt Drive Power

Press Belt Drive Power

Total Electric Power

Wash Water Pump

Compressed Air Requirement

Pneumatic Components Brand

Belt Material

Roller Material

Frame Material

Package Dimensions {Press Unit)

Package Weight {Press Unit)

Mixing Tank Dimensions

Mixing Tank Weight

Value

2000 mm

8.15 m

11.0 m

11.4 m

3.84 – 19.2 m/min (10-50 Hz)

1.38 – 6.9 m/min (10-50 Hz)

11 ( 10 pieces SS304 + 1 polymer coated roller)

16-20% DS

More than 95%

20-50 mg/L

0.75 kW, 46 rpm (SITI, Italy)

1.1 kW – SITI, Italy

1.5 kW – Nord, Germany

3.35 kW

14 m3/h@ 4-6 bar

0.1 m3/min @ 5 bar

AIRTAC

Woven Polyester Monofilament

Stainless Steel 304

SS304 I Coated Carbon Steel (as per order ogf customer)

See drawing

5000-6000 kg

1500 x 1500 x 1700 mm

85 kg