Flocculant Preparation Unit

Polymer Solution (Flocculant) Preparation Unit (PPU)

- Polymer Solution (Flocculant) Preparation and Dosing Unit

A continuous polymer solution preparation system using polyacrylamide powder, designed by Enviroflex, featuring a three-chamber stainless steel tank with three agitators. Available in 7 models with output capacities ranging from 500 to 7500 liters per hour, and adjustable solution concentrations from 0.05% to 0.4%.

The unit is fully automatic and equipped with an automated flow and concentration control system.

- Polymer Solution (Flocculant) Preparation Unit (PPU)

The Polymer Preparation Unit (PPU) by Enviroflex is a fully automatic system designed for the continuous preparation and dosing of polymer (flocculant) solution used in a wide range of applications, including:

- Municipal and industrial wastewater treatment

- Mining and mineral processing (tailings, thickening)

- Oil & gas operations (drilling fluid conditioning, produced water treatment)

- Chemical and food processing industries

Polymer solution is essential for enhancing solid-liquid separation by improving sludge and slurry flocculation before thickening, clarification, or dewatering.

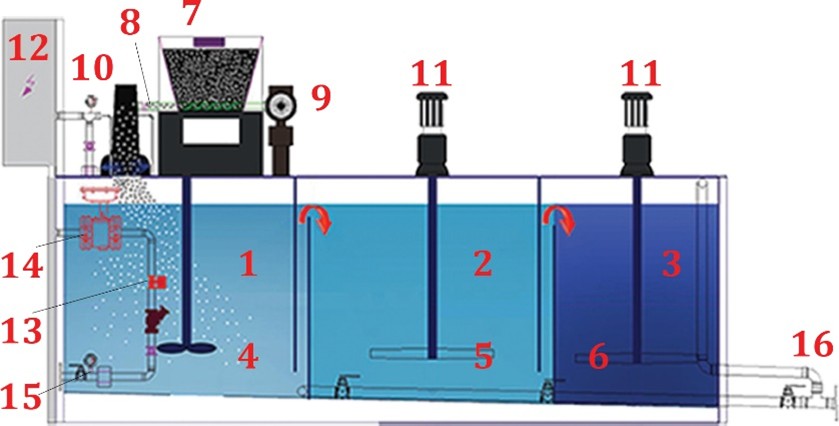

- System Description

The PPU system prepares a homogeneous, low-viscosity polymer solution by dissolving polyacrylamide powder or liquid polymer in water under controlled conditions. It operates continuously with precise concentration control, ensuring the maximum solution viscosity does not exceed 700 cP.

Key system elements:

- Powder feeding unit with a hopper and vibrator for consistent flow

- Variable-speed screw conveyor (adjustable 0.2–30 kg/h)

- Dual spray nozzles for complete wetting of polymer granules

- Three-chamber tank (Mixing – Maturing – Storage)

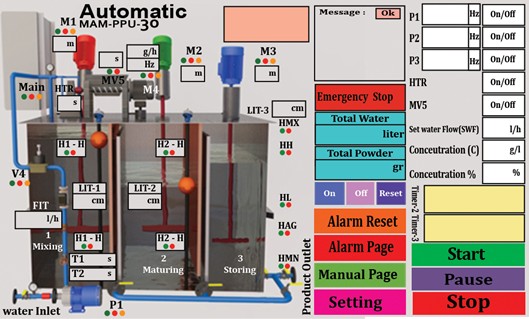

- Water flow regulation and polymer dosing automation via Siemens PLC and HMI

The water-to-polymer ratio is automatically controlled using inline flow meters and mass dosing systems to maintain target solution concentrations (typically between 0.1% and 0.4%). After initial mixing, the solution matures in the second chamber before being transferred to the storage tank for dosing.

Dosing is carried out by diaphragm or eccentric screw pumps, optionally through a Post-Dilution Unit for capacity increase or secondary dilution using fresh or treated water.

- Key Features of Enviroflex PPU

- Fully automated, continuous 24/7 operation with stable concentration output

- Suitable for polymer powders and liquids, with separate feed lines

- Applicable across sectors – wastewater, mining, oil & gas, chemical processing

- No dedicated operator required – only ~30 min/day for refilling and inspection

- Zero powder loss – 100% utilization of polymer without waste

- Consistent, lump-free polymer solution

- Post-Dilution capability – doubles capacity and enables effluent reuse

- Fast return on investment due to savings in chemical, labor, and improved process efficiency

- Construction in Stainless Steel 304 (DIN 1.4301) for corrosion resistance

- Advanced automation with Siemens PLC & SCADA, including remote access

- Easy maintenance – drainable tank design, clean-in-place features

- Adjustable output – solution concentration from 0.1% to 0.4%, up to 700 cP viscosity

Technical Specifications – Polymer Solution Preparation Units (PPU)

Model | Size 05 | Size 10 | Size 20 | Size 30 | Size 40 | Size 50 | Size 75 |

Capacity (L/h) | 500 | 1000 | 2000 | 3000 | 4000 | 5000 | 7500 |

Number of Agitators | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

Agitator 1 Motor Power | 0.75 kW | 1.1 kW | 1.1 kW | 1.5 kW | 1.5 kW | 2.2 kW | 3 kW |

Agitator 2, 3 Motor Power | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.37 kW | 0.55 kW | 0.75 kW |

Powder Feeder Gearmotor Power | 0.18 kW | 0.18 kW | 0.18 kW | 0.18 kW | 0.25 kW | 0.25 kW | 0.25 kW |

Polymer Solution Concentration (%) | 0.05–0.4 | 0.05–0.4 | 0.05–0.4 | 0.05–0.4 | 0.05–0.4 | 0.05–0.4 | 0.05–0.4 |

Tank Dimensions (W×L×H) | 830×1230× 920 mm | 1230×1580×1170 mm | 1330×2080× 1170 mm | 1580×2330×1170 mm | 2080×2580×1170 mm | 2080×3080×1170 mm | 2330×3580× |

- Mixing Section

- Polymer Maturing Section

- Solution Storage Section

- High-Speed Agitator – Mixing Section

- Low-Speed Agitator – Maturing Section

- Low-Speed Agitator – Storage Section

- Polyelectrolyte Powder Storage Tank

- Powder Feeding Screw

- Powder Feeding Gearmotor

- Powder Wetting Hopper

- Agitator Gearmotors

- Control Panel (PLC)

- Electromagnetic Flow Meter

- Motorized Control Valve

- Water Inlet

- Solution Outlet

HMI Screen in Automatic Mode