Automation

Switch Cabinet with Control Panel and Probes

The switch cabinet holds the entire control system and the monitor/panel for the visualization of the process. Also, the cables from the Oxygen and temperature probes as well as the pressure indicator are connected to a switchboard that is adjacent to each box.

Temperature: Each box has a temperature probe with cable. The probe is measuring the temperature at 5 levels of the pole.

Oxygen: Each box has an Oxygen probe with cable The probe is measuring the rel. Oxygen content in the porous air inside the waste body.

Pressure: For supervision or proper aeration conditions in a box, the pressure indicator is measuring the pressure inside the hose at the manifold.

Probes that are not used are stored with their cables on hooks that are mounted on the backside of the wall.

Starting of Process Control

General Information:

This pilot membrane composting plant consists of 4 separate compartments (composting boxes). Each box is individually aerated by a separate ventilator, controlled by the individual field instrumentation which are temperature probe, Oxygen probe, and pressure indicator. Only the leachate collection system is connected to a central leachate collection system (pump sump), interconnected through a siphon with water lock. The leachate system with respective pump is not subject to this control and visualization system.

As mentioned, each ventilator is serving one composting box, via two aeration channels per box. It has a control regime that is independently running from the other boxes.

The control system of each box is generally running through a fixed time-program, which can be influenced by the parameters of the field instruments (temperature, Oxygen, pressure).

The time program has three free adjustable “time frames”. A time frame is a period during which the aeration ratio of the ventilator is fixed (unless one or more of the mentioned parameters – temperature, Oxygen, pressure – is exceeding its threshold. For each time frame, the following parameters can be adjusted by the operator:

Duration of time frame. The duration of each of the 3-time frames can be chosen in full days, from 1 day until 21 days.

Relation between aeration time, the so-called aeration ratio, which indicates ventilator on- and ventilator off-time. This can be varied between a ratio of 1:1 and 1:5. One unit stands for 10 minutes, therefore a ratio of 1:1 means 10 minutes ventilator on, followed by 10 minutes ventilator off.

Process Control:

The composting process is started with the “Process starts in box # [box Nr.]” button at the control system.

Then, the program begins to run with the time frame 1, followed by time frame 2, followed by time frame 3. After that, the program stops and indicates “composting process in box # [box Nr.] finished”.

Process pauses: The process can be paused at any time. In this case, the elapsed time from start stops, and the ventilator stops as well. This pause is active until it is re-started. After re- start, the program continues from the time when it was paused.

This process pause can be initiated by “process pause” at the control system as well as by any emergency stop button from the field.

Process influence “temperature”:

The indicator “temperature of compost body” will be achieved from the temperature compost probe which is manually inserted into the waste body through the foreseen openings in the membrane. The probes are connected to the switch cabinet through a cable.

The temperature is registered continuously and has the following influence on the process:

- If the upper threshold temperature of 60°C is overrun for 1 min., the ventilator will be switched on for a consecutive operation time of 1 h, independently from the actual time frame presetting and aeration time that is active in the control system.

- If the lower threshold temperature of 30°C is underrun for 1 min., the ventilator will be switched off for a consecutive operation time of 1 h, independently from the actual time frame presetting and aeration time that is active in the control system.

- If the temperature probe of the respective box is actually not connected there is no process influencing “temperature”

Process influence “Oxygen”:

The oxygen probe (penetration probe) measures the oxygen concentration in the waste body during composting and controls the ventilation system. The target value of the oxygen content is > 14% by volume.

If this oxygen content drops below 14% by volume for about 1 minute, the system automatically switches to continuous ventilation for 1 hour.

This intervention is subordinate to the temperature control! If the process influences due to temperature commands a stop, it will stop, even if the Oxygen content drops below 14%.

In anyways, the Oxygen content is protocolled, so the drop below the target value can be observed and can result into manual modification of the aeration procedure (parameter adjustment).

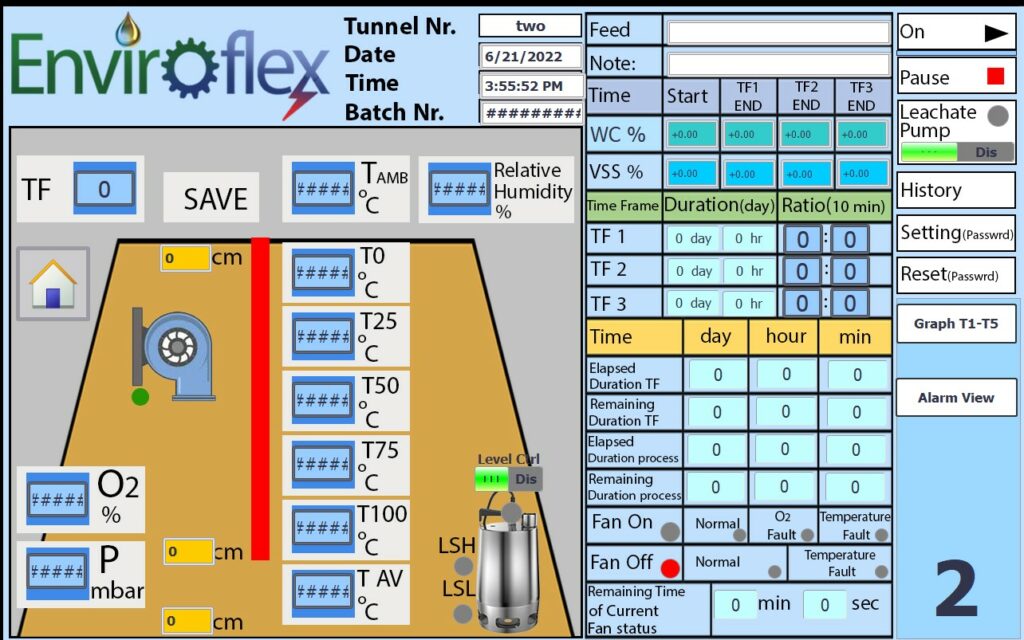

Visualization

Starting screen:

The starting screen shows all 4 composting compartments. It shows which one is in progress and which one is on pause or not active. It also shows the time frame in which each box is, if it is active.

Sub screen #1:

When clicking on one of the 4 boxes, the sub-screen #1 opens. This screen shows one box. If it is not in operation, it is shown empty. If it is in operation or pause, it is shown filled.

The following parameters sand more are shown:

- Box Nr. [1…4]

- Active time frame [1…3]

- Active aeration ratio [1:x]

- Elapsed time and remaining time of motor on/motor off [minutes]

- Elapsed time and remaining time in time frame [days]

- Elapsed time from composting start and remaining time until composting end [days]

- Temperature [°C]

- Oxygen [%]

- Pressure [Pa]

The temperature and Oxygen probe are shown in the waste body in green, if they are connected and provide measuring results. They are shown grey if they are not connected or do not provide measuring results.

If the process is paused, this is indicated as a sign in red.

Sub screens

If the operator selects the parameters, this will lead into sub screen, where the parameters pre-setting and thresholds can be seen and modified.

The other sub-screen will allow the reporting and trends of the measured parameters.

The total operating hours of each ventilator are logged and cannot be edited or erased by the operator.

4.5. HMI and command and operation of control panel (Monitoring Operating Manual):

Brief Description of system:

This pilot membrane composting plant consists of 4 separate compartments (composting boxes). Each box is individually aerated by a separate ventilator, controlled by the individual field instrumentation which are temperature probe, Oxygen probe and pressure indicator.

Only the leachate collection system is connected to a central leachate collection system (Pump sump), interconnected through a siphon with water lock. The leachate system with respective pump is not subject to this control and visualization system. As mentioned, each ventilator is serving one composting box, via two aeration channels per box. It has a control regime that is independently running from the other boxes. The control system of each box is generally running through a fixed time-program, which can be influenced by the parameters of the field instruments (temperature, Oxygen, pressure).

Contact

-

Enviroflex GmbH

Sterngasse 3/2/6

1010 Vienna

Austria - +43 1 532 01 80-235

- office(at)enviroflex.at

Business Sector

EXHIBITIONS & PRESENTATIONS

-

Lubricant Expo North America

Americas's Largest Dedicated

Exhibition & Conference -

19 - 21 March 2024

Huntington Place - Detroit, Michigan, USA

Booth 724 Enviroflex GmbH - https://lubricantexpona.com/