Distilled Oil Polishing Unit (DOPU)

Unique Process Technology

- Polishing/filtration of Black distilled lube Oil

- Polishing by passing from Sorbent inside different columns

- Usage Activated Sorbent

- Reduction of Colour Index, Sulphur, Acidity, and smell of distilled oil

- Possibility to producer API Group I, API Group II and API Group III base oil

- Continuous operation, 6 hours per day polishing, and 18 hours per day reactivation period

- UP to 500 times Sorbent reactivation

- Proper for lube oil, Diesel, and other hydrocarbons

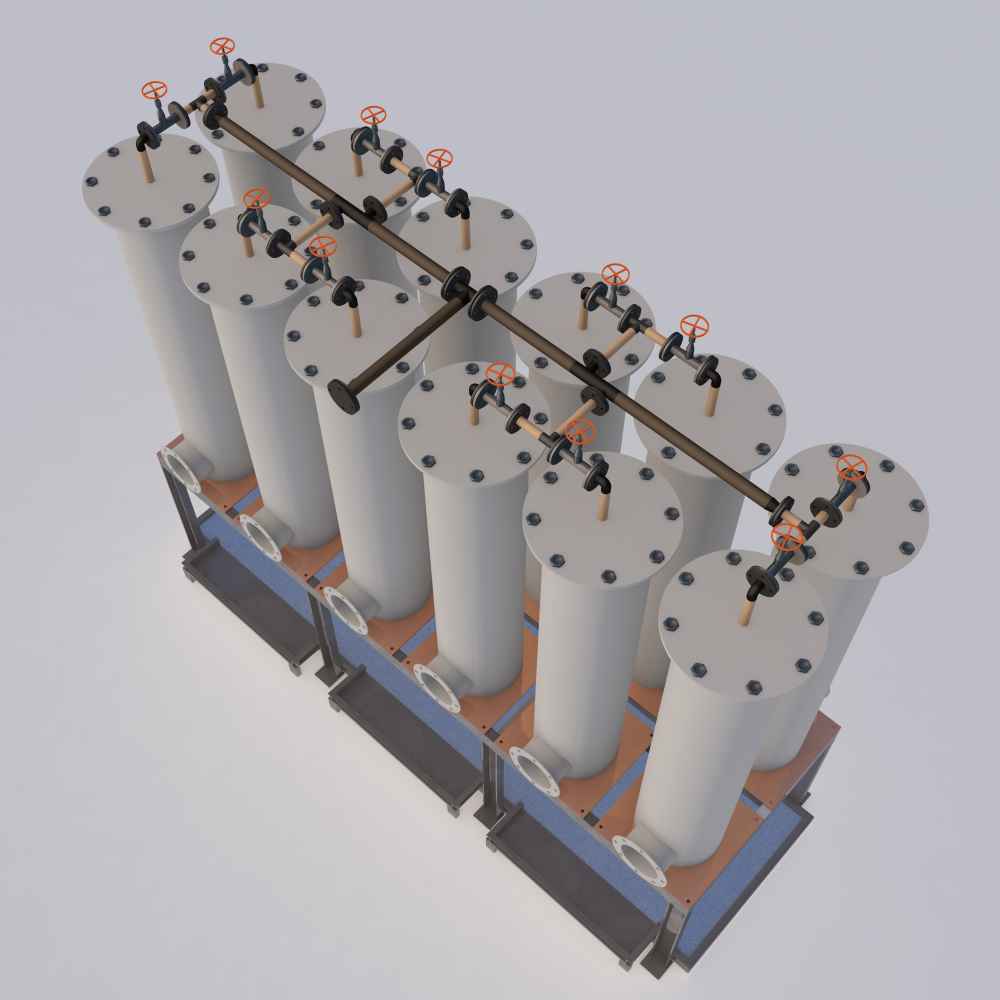

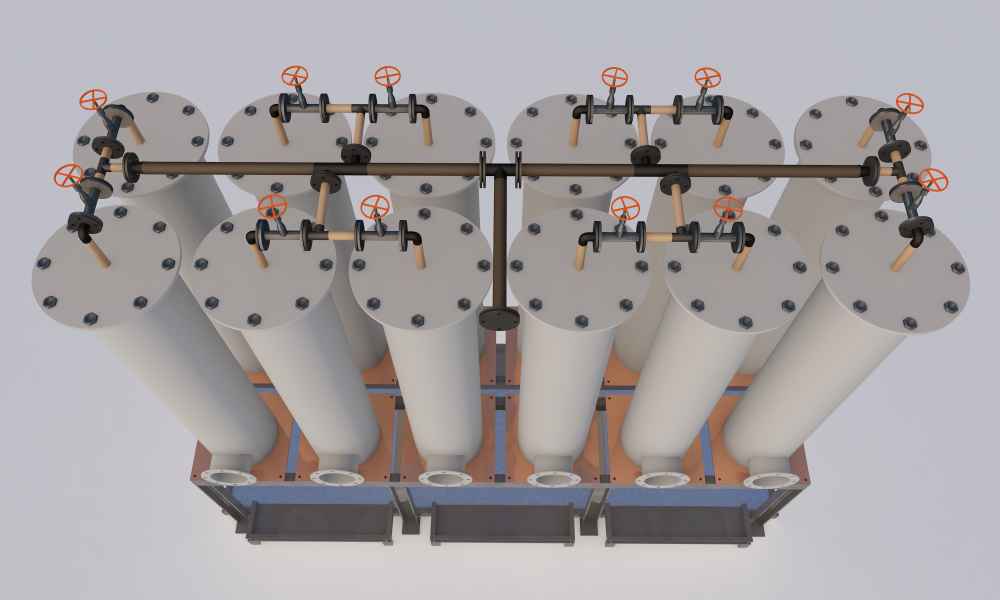

- Up to 4 banks of 30 columns, Independent Roots Blowers for each bank

- No Re-turbidity. 98% efficiency, only about 2% high sulfur oil

- Different sizes from 1 to 144 columns, Long Columns

- Different feed capacities from 250 kg/day to 81 tons/day

- High settable efficiency up to 99% according to the inlet oil quality

- Delivery of our formulated developed Sorbent at our brand

Specification of Polished Oil:

Color Index: 0.5 to 2.0 according to ASTM D1500

Sulphur: 250 to 1200 ppm according to ASTM D2622

Acidity: 0.01-0.02 mgKOH/gm according to ASTM D974

Up to 4 (four) 30-Column Banks

Independent Roots Blowers for each bank

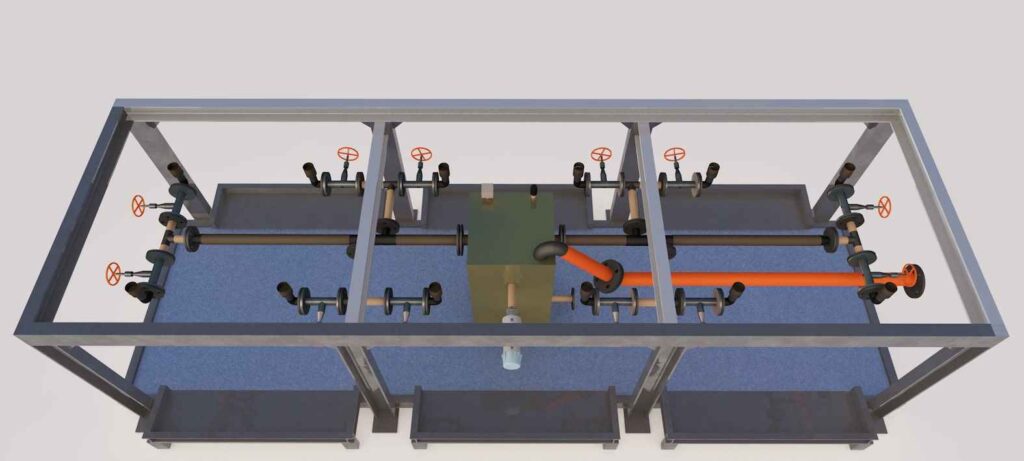

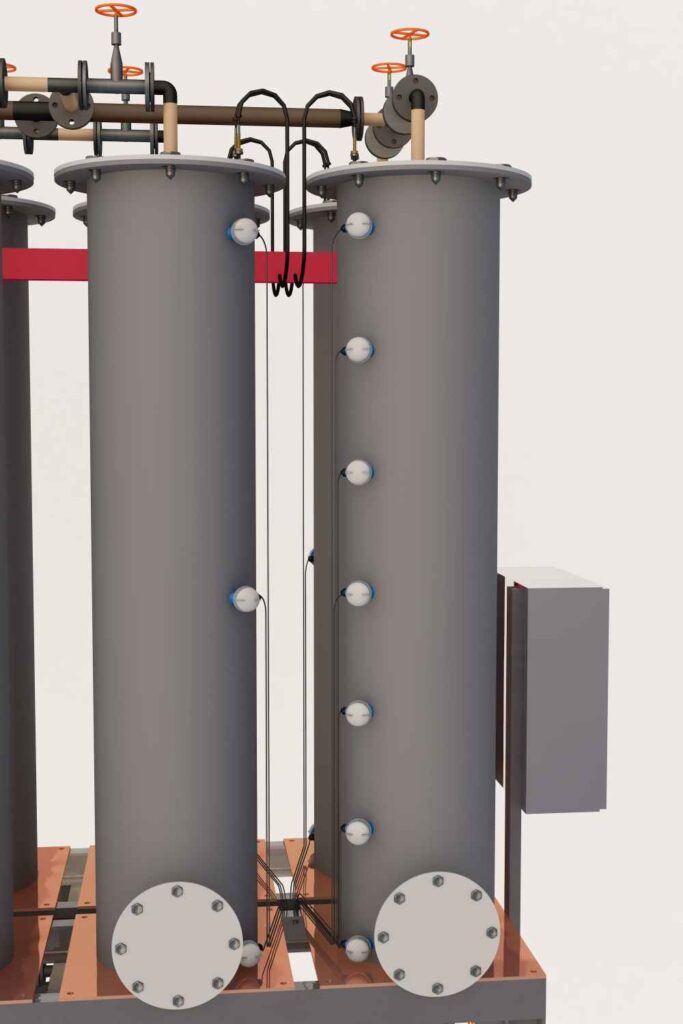

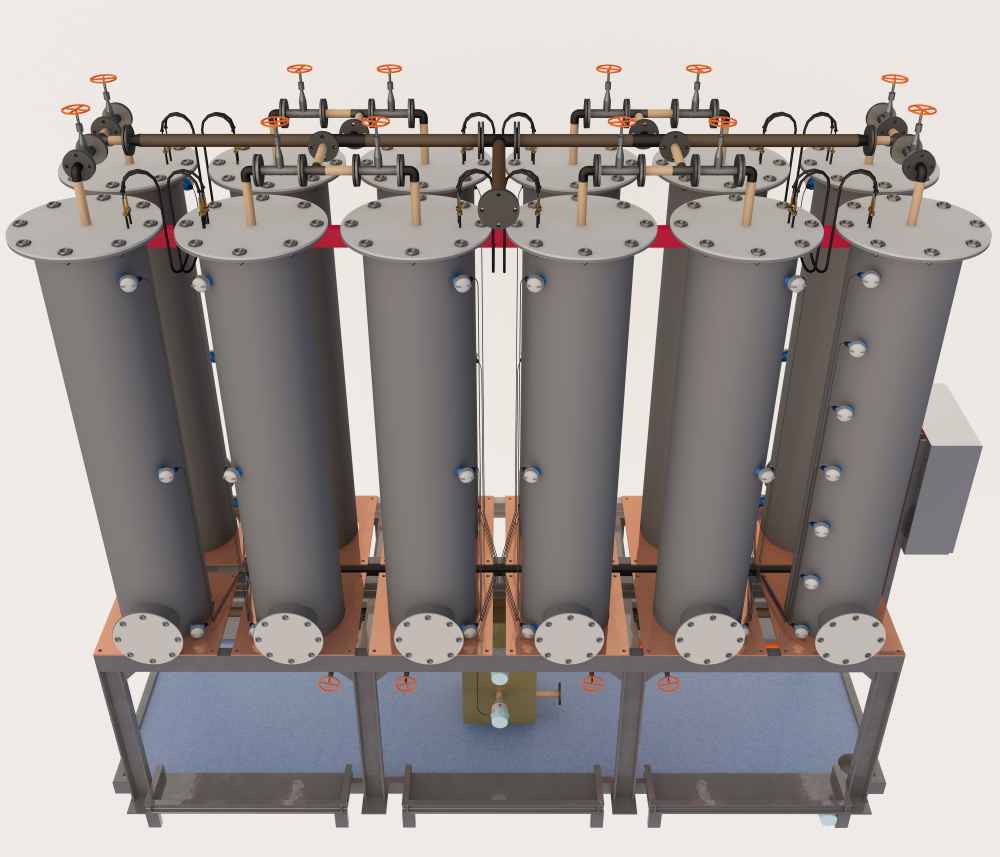

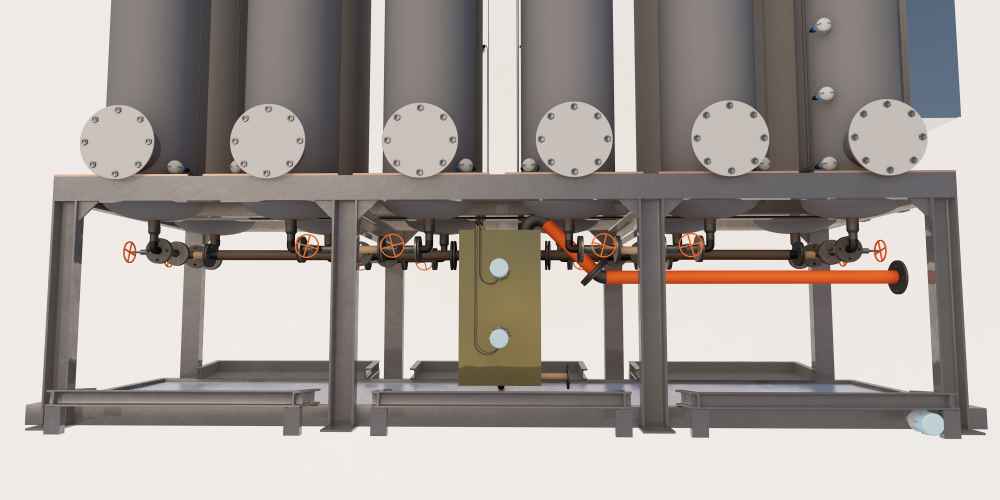

Different Views of a Skid of Columns - Black Distilled Oil Polishing Units (12 Columns in 1 Bank)

Contact

-

Enviroflex GmbH

Sterngasse 3/2/6

1010 Vienna

Austria - +43 1 532 01 80-235

- office(at)enviroflex.at

Business Sector

EXHIBITIONS & PRESENTATIONS

-

Lubricant Expo North America

Americas's Largest Dedicated

Exhibition & Conference -

19 - 21 March 2024

Huntington Place - Detroit, Michigan, USA

Booth 724 Enviroflex GmbH - https://lubricantexpona.com/