Transformer Oil Regeneration Unit (TORU)

Unique Process Technology

Aging transformer oil forms sludge. Sludge attacks the cellulose insulation, inhibits oil flow, and traps heat inside the transformer. Eventually, the dielectric gap is bridged, resulting in the failure of the transformer.

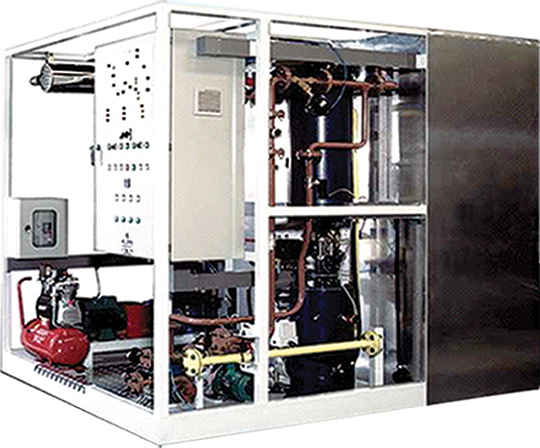

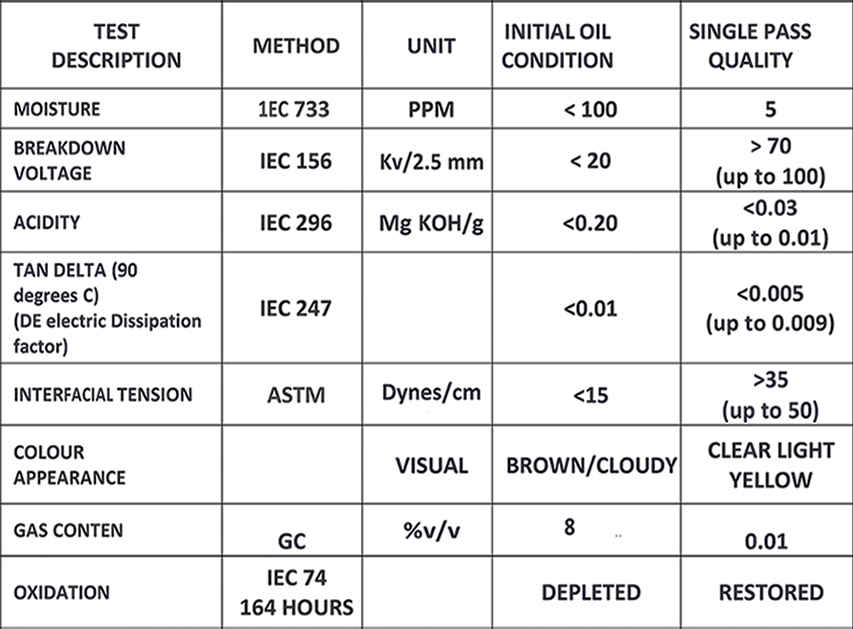

Enviroflex Transformer Oil Regeneration Unit (TORU) removes acidity, sludge, and soluble oil decay products with our special developed Sorbent. When the treatment is complete, the regenerated oil meets or exceeds international standards for new oil with lower acidity and improved tan delta, interfacial tension, and oxidation stability.

The cellulose insulation and internal components of the transformer also benefit from the flushing effect of multiple passes of hot reclaimed oil, which helps remove decay products and sludge from surfaces.

Regular regeneration treatments every eight to twelve years:

- Reduced risk of unplanned outage and costly downtime

- Reduced maintenance costs.

Environmentally Friendly Electrical Power Systems | Regeneration of aged Transformer Oil to new condition according to IEC 60422 & IEC 60269 |

Using Mineral Sorbent for Oil Regenration | Different capacities 500 I/h to 10,000 I/h |

Features:

- Reactivation by sorbent with the possibility of 300 times reactivation

- Support on energized and non-energized transformers

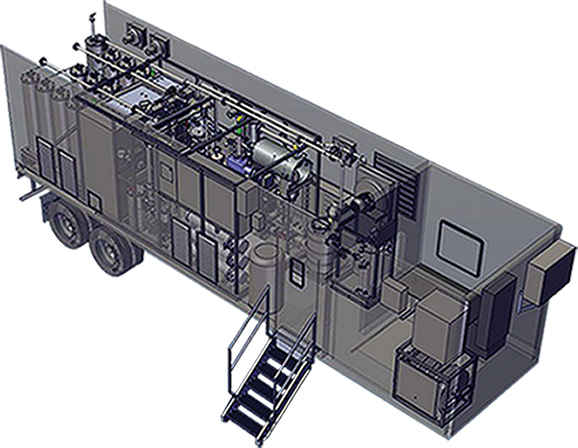

- Flow rates vary from 600 to 10000 liters per hour

- Oil processing capacity from 1000 to 15000 liters per cycle

- Fully Automated controls

Contact

-

Enviroflex GmbH

Sterngasse 3/2/6

1010 Vienna

Austria - +43 1 532 01 80-235

- office(at)enviroflex.at

Business Sector

EXHIBITIONS & PRESENTATIONS

-

Lubricant Expo North America

Americas's Largest Dedicated

Exhibition & Conference -

19 - 21 March 2024

Huntington Place - Detroit, Michigan, USA

Booth 724 Enviroflex GmbH - https://lubricantexpona.com/