Composting Plant

Membrane Covered Composting Plant

Enviroflex GmbH offers a pressurized aeration process in concrete tuneless (Boxes) covered by a semipermeable membranes process. It is a simple, easy to build, and very cost-efficient project. Thanks to Covering the feed by Membrane, the odour insects and birds are minimized around the plant.

Product details:

Composting Plant PDF

More questions:

Tel.: +43 1 53 20 180 – 235

office(at)enviroflex.at

These plants can be used for these applications:

- Composting of the organic part of MSW

- Composting of Biowaste and green waste composting

- Composting of digested or sewage sludge

- Biological stabilization to reach the parameters of landfill directives

- Biological drying prior to incineration

- Production of refused derived fuel (RDF)

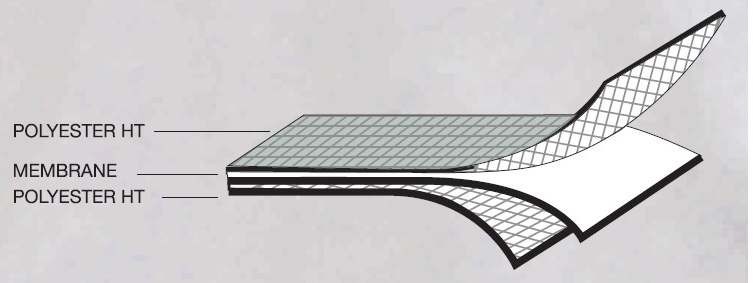

The applied three-layer laminate is based on an antibacterial inner layer, a UV-stabilized outer layer, and the proper functional and breathable membrane as an intermediate layer.

Due to the combination of these layers to the composite material, the achieved performance allows high breathability for vapor, highest possible retention concerning odor, dust, and germs, prevention of rainwater penetration, sturdiness in handling, and long product durability.

To improve the wear resistance, the outside edges are protected with tarpaulin which also holds the loops and back straps for easy handling, winding, and fixing. To ensure the correct insertion of the probes into the substrate, necessarily required for an appropriate process control, special openings are stitched off.

Enviroflex GmbH can offer this technology in the following configuration:

- Windrows or piles: simplest solution, pressurized aeration on a sealed surface.

- Concrete Tuneless or Boxes: The membrane is spread over the surface of the substrate between the concrete sidewalls an entirely seals the box.

Depending on the size of the membrane, the handling is either done manually or mechanically operated by designed cover placement.

The supply of fresh air and the discharge of leachate are reached by special aeration ducts in the floor.

Equipment of the Plant ⚙

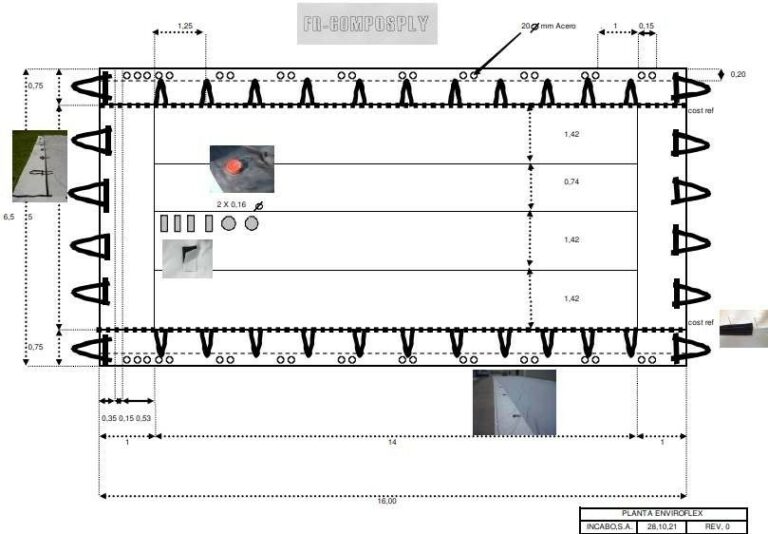

Composting Boxes or Tunnels

The plant consists of several compartments (Tunnels or boxes) with different sizes and volume. Each box is individually filled, aerated and discharged. The box slab and walls are made of reinforced concrete that withstands the temperature of composting as well as the operation by wheel loader.

Aeration Ducts with Slotted Plates

The slab of each box is holding two aeration ducts. The ducts are reinforced with metal profiles and closed with slotted PE plates. The slots have a size to allow sufficient air to go through from the ducts into the waste body and avoid waste falling through it into the ducts as good as possible. They have to be cleaned and checked regularly.

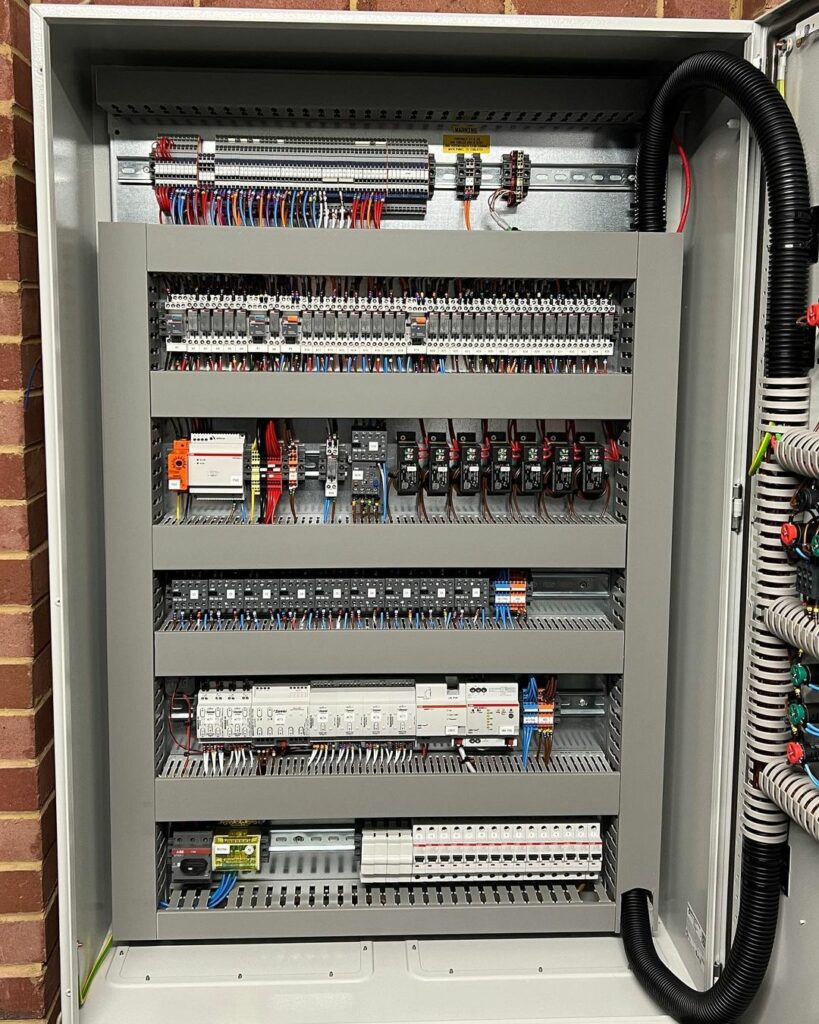

Switch Cabinet with Control Panel and Probes

The switch cabinet holds the entire control system and the monitor/panel for the visualization of the process. Also, the cables from the Oxygen and temperature probes as well as the pressure indicator are connected to a switchboard which is adjacent to each box.

Temperature: Each box has a temperature probe with cable. The probe is measuring the temperature at 5 levels of the pole

Oxygen: Each box has an Oxygen probe with cable The probe is measuring the rel. Oxygen content in the porous air inside the waste body.

Pressure: For supervision or proper aeration conditions in a box, the pressure indicator is measuring the pressure inside the hose at the manifold.

Ventilators (Fans) with Distribution Manifold

Each box has a radial ventilator to press the ambient air into the aeration ducts under the compositing material. Each ventilator is individually controlled by the control system.

The ventilator has a protection mesh to avoid leaves or larger particles to be sucked in into the rotor. At the exit side the hose is leading to a manifold (Y-shape) which is providing the compressed air into the two aeration ducts of each box.

At the manifold there is a pressure indicator to survey proper pressure inside the system. The pressure is indicated at the visualization of the PLC.

Membranes

The size and shape of the membranes are proper for size of boxes with outside edges protected with tarpaulin which are holding the loops and back straps for easy handling.

The applied three-layer laminate is based on an antibacterial inner layer, a UV-stabilized outer layer and the proper functional and breathable membrane as intermediate layer. Due to the combination of these layers to the composite material, the achieved performance allows high breathability for vapour, highest possible retention concerning odour, dust and germs, prevention of rainwater penetration, sturdiness in handling and long product durability.

Underground Leachate Collection with Sump Pump

and Syphon

The aeration ducts are followed by the leachate collection underground pipes made of PVC. They are conveying the leachate which comes from the fresh waste of from the humidification into the collection pit. In the collection pit, all 4 pipes (one from each box) are

collected. They are arranged below water level to allow a water lock, that the pressure inside the aeration system can be used to press the air through the waste body.