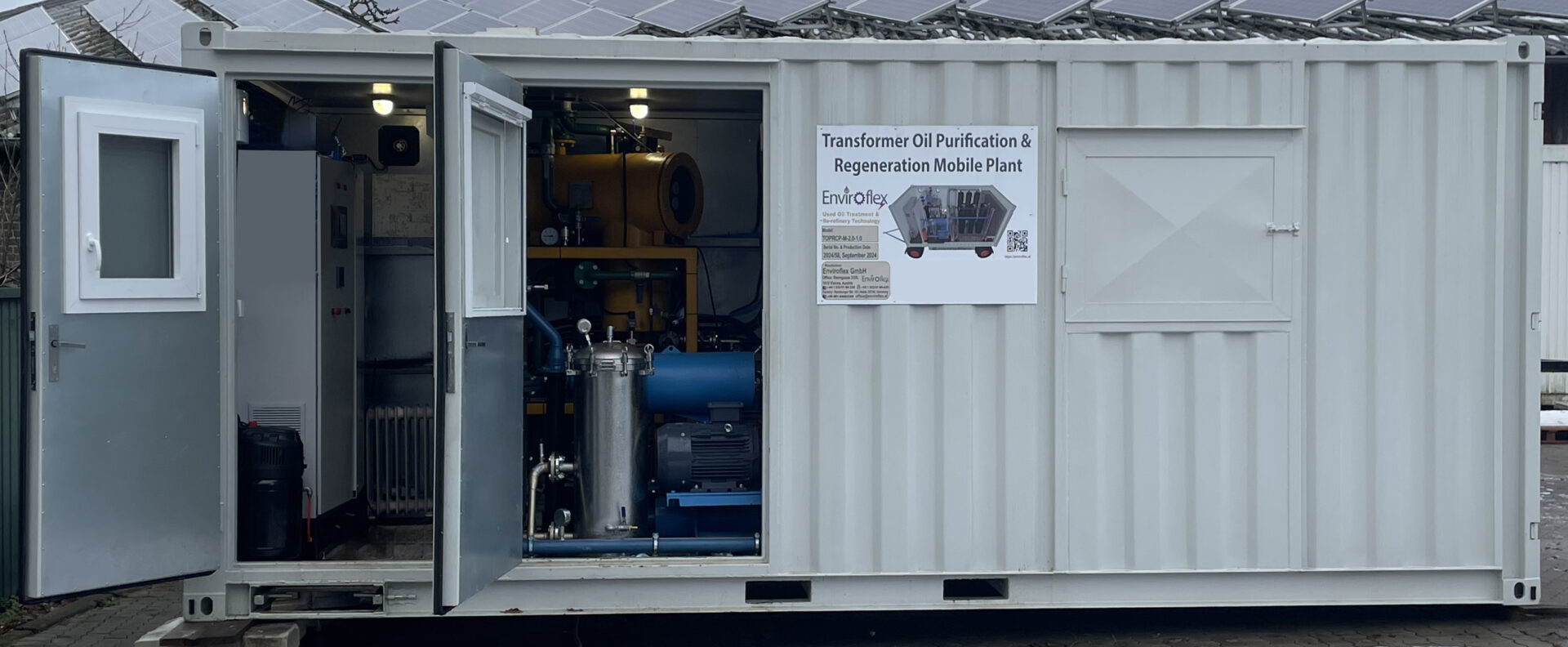

Transformer Oil Purification & Regeneration Mobile Plant

Premium Transformer Oil Purification & Regeneration Mobile Plant – Available Now!

Now available for immediate delivery, the Transformer Oil Purification & Regeneration Mobile Plant is a cutting-edge solution for efficient oil treatment. Designed and manufactured in Germany by Enviroflex Altöltechnik GmbH, this mobile system ensures high performance and reliability for both on-load and off-load transformer oil purification.

Key Features:

- Immediate Availability: Delivered within 2 weeks—no waiting time.

- High Capacity: Processes up to 2000 L/H of transformer oil with 6 regeneration columns that can be reactivated up to 500 times.

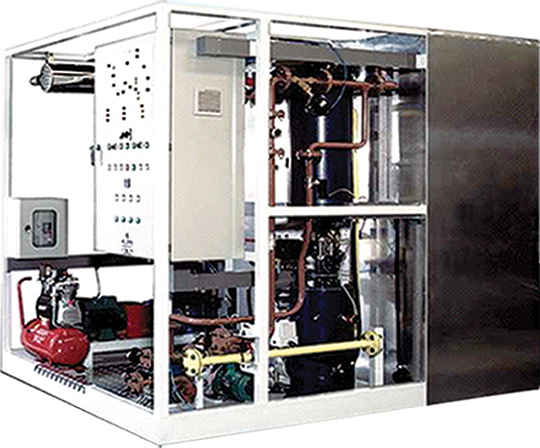

- Advanced Filtration System: Equipped with a vacuum chamber, coalescence filters, indirect electric heating, and 0.5 µm cartridge filters for superior oil purification.

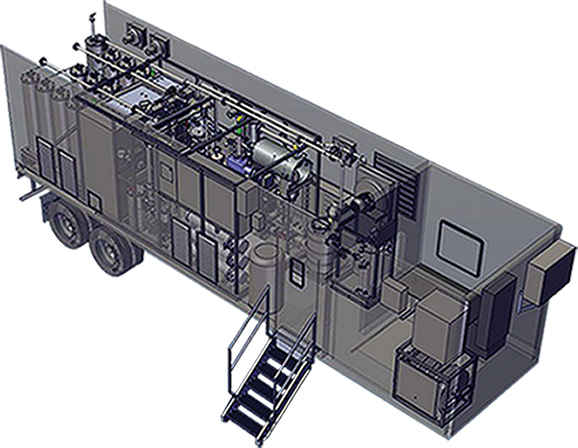

- Mobile & Flexible: Fully mobile unit, ideal for both on-load and off-load operations, featuring a reliable Krone thriller.

- Compact & Efficient Design: Housed in a 20-foot container divided into three separate rooms for optimized space and functionality.

- IEC Standard Compliance: Delivers high-quality, regenerated transformer oil that meets the highest industry standards.

Take advantage of this premium, ready-to-deploy solution for your transformer oil regeneration needs. Available for immediate delivery—order now!

+49 176 15112890

Transformer Oil Regeneration Unit (TORU)

Unique Process Technology

Aging transformer oil forms sludge. Sludge attacks the cellulose insulation, inhibits oil flow, and traps heat inside the transformer. Eventually, the dielectric gap is bridged, resulting in the failure of the transformer.

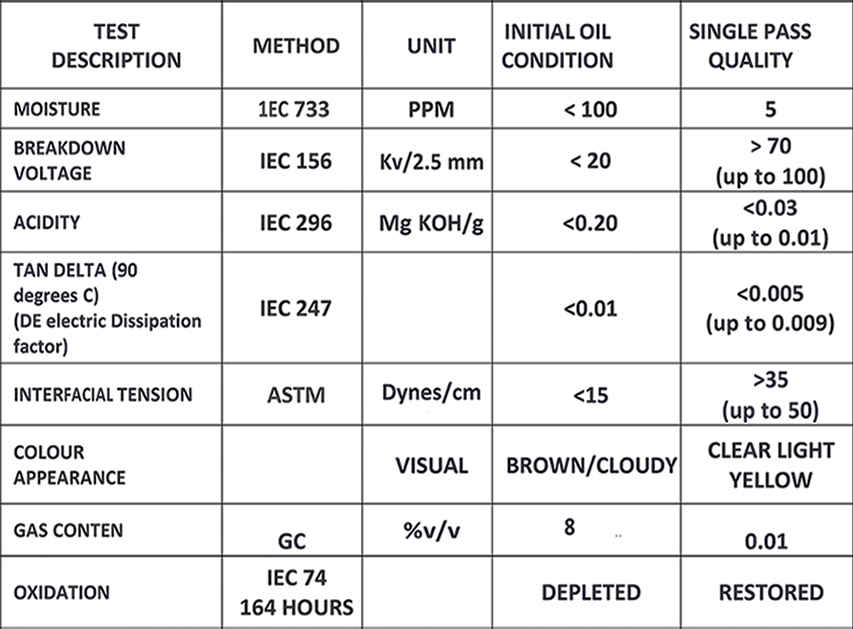

Enviroflex Transformer Oil Regeneration Unit (TORU) removes acidity, sludge, and soluble oil decay products with our special developed Sorbent. When the treatment is complete, the regenerated oil meets or exceeds international standards for new oil with lower acidity and improved tan delta, interfacial tension, and oxidation stability.

The cellulose insulation and internal components of the transformer also benefit from the flushing effect of multiple passes of hot reclaimed oil, which helps remove decay products and sludge from surfaces.

Regular regeneration treatments every eight to twelve years:

- Reduced risk of unplanned outage and costly downtime

- Reduced maintenance costs.

Environmentally Friendly Electrical Power Systems | Regeneration of aged Transformer Oil to new condition according to IEC 60422 & IEC 60269 |

Using Mineral Sorbent for Oil Regenration | Different capacities 500 I/h to 10,000 I/h |

Features:

- Reactivation by sorbent with the possibility of 300 times reactivation

- Support on energized and non-energized transformers

- Flow rates vary from 600 to 10000 liters per hour

- Oil processing capacity from 1000 to 15000 liters per cycle

- Fully Automated controls