Used Oil Re-refinery

Used Oil Re-refinery

Production of Base Lube Oil & Distilled Fuel from Used Motor Oil

- Evaporation/Distillation process under high vacuum

- Polishing/ Decolorization by Activated Sorbent

- Sorbet Reactivation hunderts of times in the system.

- NMP Solvent Treatment/Recovery as an option

- Environment-friendly Process, Zero discharge

- Different plant feed amount, 1 ton/day up to 100 ton/day

- Base Oil with quality API Group I & distilled fuel as final products

- API Group II quality with combination of NMP Solvent treatment/Recovery

- Heavy hydrocarbon Residue used at Asphalts Factories

- Low evaporation temperature, Max. 305° C (preventing any cracking)

- High Vacuum Pressure, up to 0.4 mbar

- Different oil viscosities by vacuum setting and several distillations

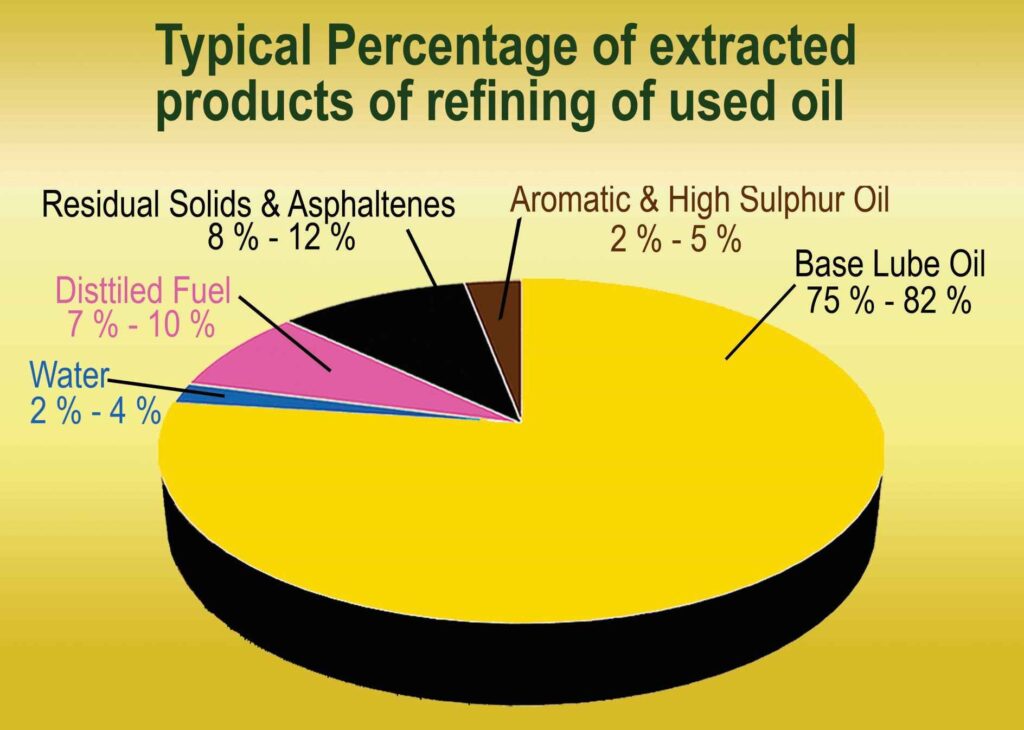

- Maximum base Lube Oil recovery up to 82%

- Product without any bad smell

- No emission, usage of scrubber, activated carbon filter or flare for preventing any pollution

Enviroflex GmbH

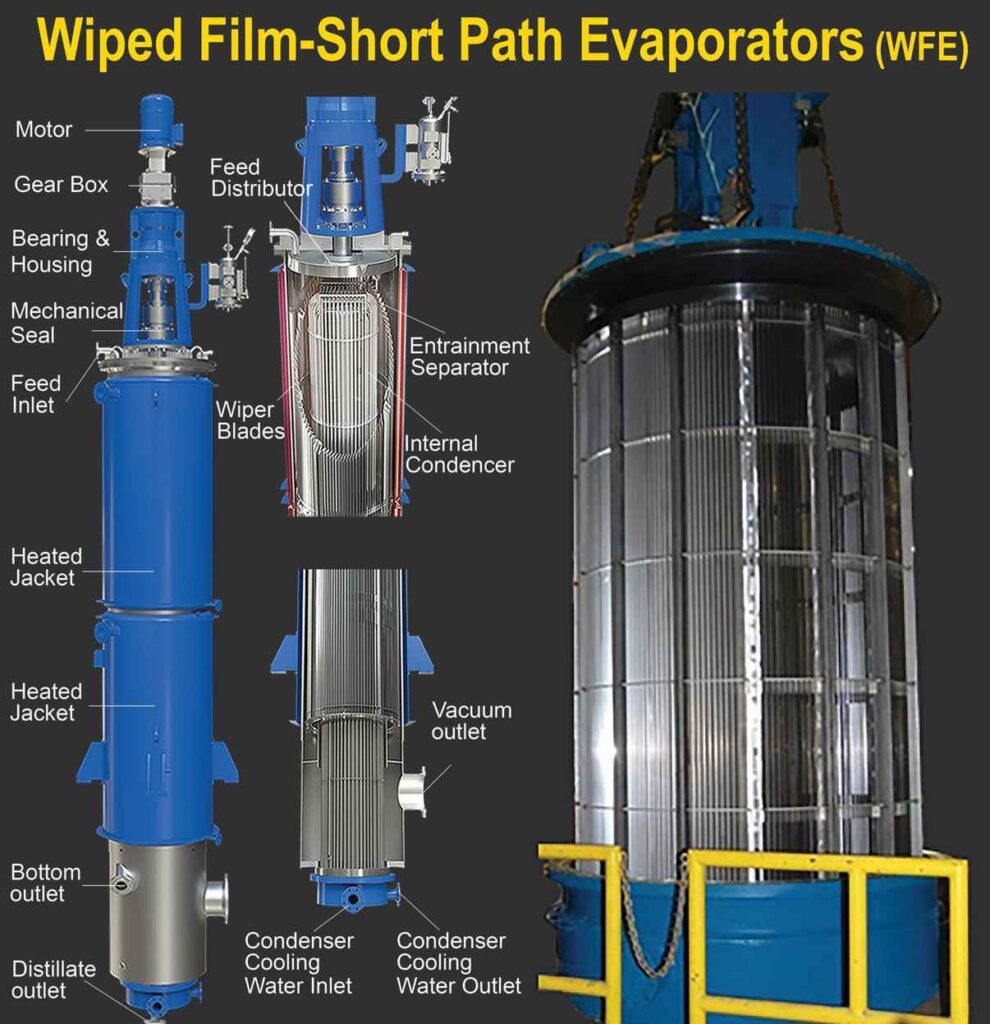

supplies Wiped Film-Short Path Evaporators (WFE) with condenser inside the columns as a part of a complete used oil Re-refinery.

The standard sizes are from 0.1 sqm to 21.5 sqm evaporation surface area.

Enviroflex GmbH also delivers multi-stage vacuum system to reach high vacuum up to 0.4 mbar

at 305 °C during operation.

Enviroflex GmbH also integrates the system by adding external condenser and cold trap to eliminate hydrocarbons and odors.